How Collapsible Sleeves Cut Freight Costs

- Sales Lead

- Nov 21

- 3 min read

Introduction: Freight Costs as a Supply Chain Challenge

Freight costs are one of the largest expenses in modern logistics. Whether moving goods across regions or internationally, companies face constant pressure to reduce transportation costs while maintaining efficiency. Traditional single‑use packaging often adds to the problem, creating inefficiencies in cube utilization and forcing businesses to pay for wasted space during return shipments. As industries search for smarter solutions, collapsible sleeves have emerged as a practical innovation that directly addresses freight cost challenges. At Returnable Asset Packaging, we design reusable folding sleeves that collapse flat, reduce cube space, and deliver measurable savings across the supply chain.

---

The Inefficiency of Single‑Use Packaging

Single‑use packaging may seem convenient, but it creates hidden costs that erode profitability. Once products are delivered, companies often face the challenge of returning empty containers. These containers take up the same amount of space as full shipments, meaning businesses pay to transport air. In addition, bulky single‑use packaging consumes valuable warehouse space, increasing storage costs. Over time, these inefficiencies add up, creating a significant financial burden. By contrast, collapsible sleeves are designed to fold flat, minimizing wasted space and reducing both freight and storage expenses.

---

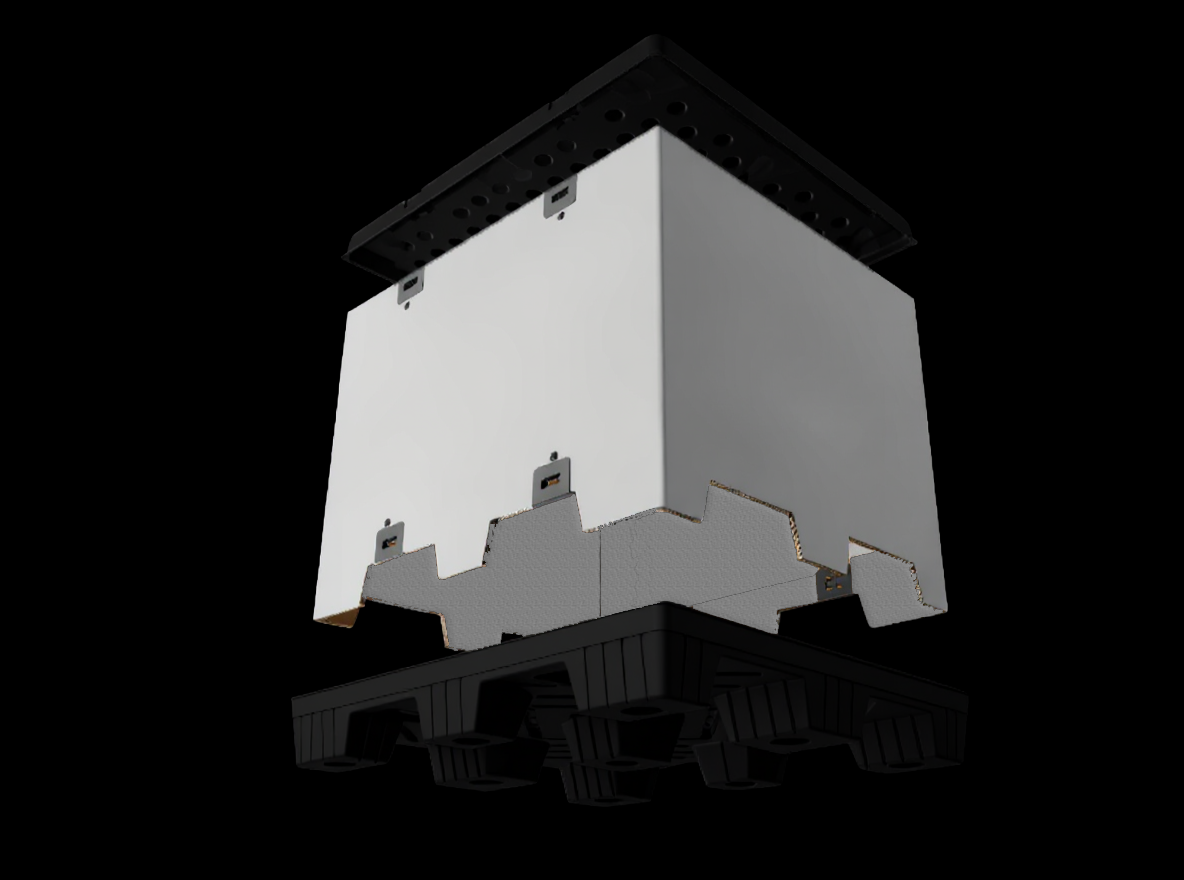

Collapsible Sleeves: A Smarter Alternative

Collapsible sleeves provide a simple yet powerful solution. Built from durable plastic, they are engineered to withstand repeated trips while offering the flexibility to collapse when not in use. This design reduces cube space during backhaul, allowing companies to transport more units per truckload or minimize the number of trucks required. At Returnap.com, our reusable sleeve systems integrate seamlessly with standard pallets and tops, meaning businesses don’t need to redesign their operations. The result is a packaging system that delivers both cost savings and operational efficiency.

---

Financial Impact Across Industries

The savings from collapsible sleeves are significant. By reducing cube space, companies lower freight costs on return shipments, often cutting expenses by double‑digit percentages. Storage costs are also minimized, as collapsed sleeves take up far less warehouse space than bulky single‑use alternatives. For industries such as automotive, food, and pharmaceuticals, where logistics volumes are high, these savings quickly compound into substantial financial gains. Over the life of a program, reusable sleeves deliver lower total landed costs, making them a smarter long‑term investment compared to expendable packaging.

---

Environmental Benefits and Sustainability Goals

Collapsible sleeves don’t just save money — they also support sustainability initiatives. By replacing single‑use packaging with durable, reusable systems, companies reduce landfill waste and improve environmental performance. This aligns with growing regulatory requirements and consumer expectations for sustainable practices. At Returnable Asset Packaging, we design solutions that help businesses achieve measurable sustainability metrics, from reduced waste to improved cube utilization. Collapsible sleeves are more than a logistics innovation — they’re a sustainability strategy that strengthens corporate responsibility.

---

Real‑World Applications

Collapsible sleeves are already proving their value across multiple industries.

Automotive: High‑volume parts shipments benefit from rugged sleeves that withstand repeated trips.

Food Distribution: Perishable and non‑perishable goods are protected while reducing freight and storage costs.

Pharmaceuticals: Sensitive products are transported securely, with sleeves supporting hygiene and sustainability standards.

Distribution Centers: Standardized footprints integrate seamlessly into racks and pallets, streamlining operations.

ch of these applications demonstrates how collapsible sleeves deliver universal benefits while meeting industry‑specific needs.

---

Conclusion: Cutting Costs and Building Efficiency

Freight costs will always be a challenge in logistics, but collapsible sleeves provide a proven way to reduce them. By folding flat for return shipments, minimizing storage space, and delivering long‑term durability, they offer both financial and environmental advantages. At Returnap.com, we provide standardized, reusable sleeve systems that drop straight into existing operations, making adoption simple and cost‑effective. Collapsible sleeves are more than packaging — they’re a logistics strategy that directly impacts profitability, sustainability, and resilience across the supply chain.

Comments