The Future of Reusable Packaging in Supply Chains

- Sales Lead

- Nov 21, 2025

- 3 min read

Introduction: Why Packaging Needs to Change

Supply chains are the lifeblood of modern commerce, moving goods from manufacturers to distributors, retailers, and ultimately to consumers. Yet one of the most overlooked aspects of this process is packaging. For decades, single‑use packaging has dominated logistics, creating mountains of waste, inflating costs, and straining operations. As industries face mounting pressure to reduce environmental impact and improve efficiency, reusable packaging has emerged as a transformative solution. At Returnable Asset Packaging, we believe the future of packaging lies in systems that are durable, standardized, and designed for repeated use.

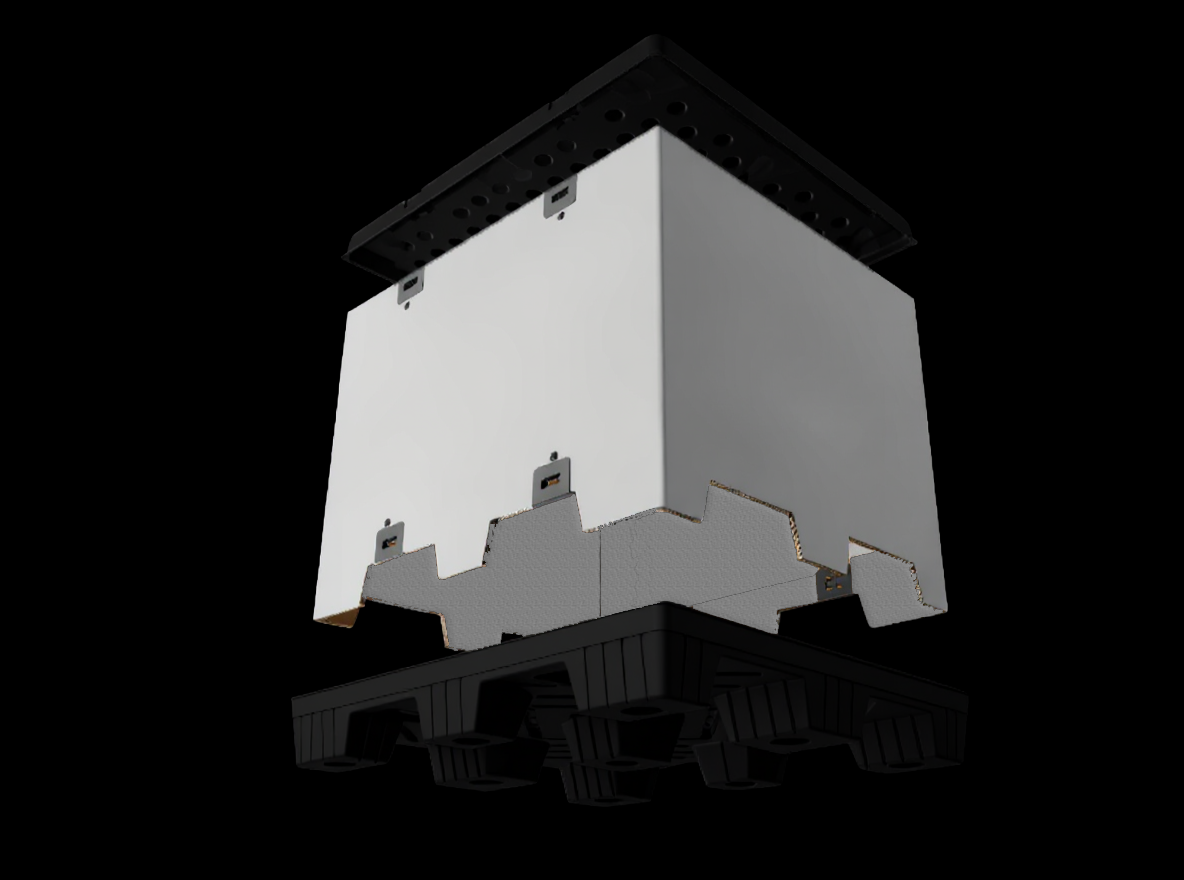

The Rise of Reusable Sleeve Systems

Reusable sleeve systems are at the forefront of this shift. Unlike expendable packaging, these sleeves are built to withstand years of handling, collapse flat for return shipments, and integrate seamlessly with standard pallets and tops. This means companies don’t need to redesign their racks, tools, or line layouts — the sleeves drop straight into existing operations. At Returnap.com, our solutions are engineered for real‑world logistics, offering both cost savings and sustainability benefits. By adopting reusable sleeves, businesses can lower total packaging costs, reduce single‑use waste, and improve cube utilization.

Cost Savings Across the Supply Chain

One of the most compelling reasons to adopt reusable packaging is the financial impact. Freight costs are a major expense in logistics, and collapsible sleeves directly address this challenge. By folding flat, they minimize cube space during return shipments, cutting freight costs significantly. Storage costs are also reduced, as collapsed sleeves take up far less warehouse space than bulky single‑use containers. Over the life of a program, reusable sleeves deliver lower total landed costs compared to expendable packaging. For industries like automotive, food, and pharmaceuticals, where high‑volume shipments are the norm, these savings add up quickly.

Environmental Benefits and Sustainability Goals

Beyond cost savings, reusable packaging supports corporate sustainability initiatives. Single‑use packaging contributes to landfill waste and environmental degradation, while reusable sleeves reduce this impact by replacing disposable materials with durable, returnable systems. Companies that adopt reusable packaging demonstrate leadership in sustainability, meeting regulatory requirements and consumer expectations. At Returnable Asset Packaging, we design solutions that help businesses achieve measurable sustainability metrics, from reduced waste to improved cube utilization. This isn’t just about compliance — it’s about building a cleaner, more resilient supply chain for the future.

Industries Leading the Way

Several industries are already embracing reusable packaging as a competitive advantage.

Food Industry: Reusable sleeves protect perishable and non‑perishable goods, streamline distribution, and reduce waste.

Pharmaceuticals: Smooth, durable surfaces support hygiene standards in clean rooms and hospital supply chains.

Distribution Centers: Standardized footprints integrate seamlessly into racks and pallets, improving efficiency and reducing costs.

Automotive: High‑volume parts shipments benefit from rugged, reusable sleeves that withstand repeated trips.

ch of these industries demonstrates how reusable packaging can be tailored to specific needs while delivering universal benefits.

Customization and Branding Opportunities

Packaging is more than a logistics tool — it’s also a branding opportunity. At Returnap.com, we offer customization options that allow companies to select colors and add logos to their reusable sleeves. This enhances visibility in warehouses and distribution centers, reinforces corporate identity, and simplifies product segmentation. Custom branding ensures that packaging not only performs but also promotes the brand across every stage of the supply chain.

Building a Resilient Supply Chain

Resilience is critical in today’s global supply chains. Disruptions caused by economic shifts, environmental regulations, or logistical bottlenecks can have far‑reaching consequences. Reusable packaging strengthens resilience by reducing dependence on expendable materials, supporting circular logistics models, and ensuring consistent performance across repeated trips. Standardized, proven designs allow for faster deployment, making supply chains more adaptable to change. At Returnable Asset Packaging, we see reusable sleeves as a cornerstone of resilient, sustainable logistics.

Looking Ahead: What’s Next in Returnable Packaging

The future of reusable packaging is bright, with innovations on the horizon that will expand its impact. At Returnap.com, we are developing new solutions, including pallet bases, secure lids, and complete system kits. These additions will provide even greater flexibility and efficiency, supporting industries across the supply chain. As more companies adopt reusable packaging, the benefits will compound — lower costs, reduced waste, stronger branding, and improved resilience.

Conclusion: A Smarter, Cleaner Supply Chain

Reusable packaging is no longer optional; it’s essential for companies that want to remain competitive, sustainable, and efficient in a rapidly evolving global market. By adopting reusable sleeve systems, businesses can achieve lower costs, reduce waste, and build a more resilient supply chain. At Returnable Asset Packaging, we are proud to lead this transformation, offering solutions that combine durability, standardization, and customization. The future of packaging is here — and it’s reusable.

Comments